Everfoton's laser adopts all-fiber structure, with small fiber diameter and high power density inside the fiber. In the process of use, if the laser QBH output head is dirty or improperly cleaned, it tends to cause serious damage to the QBH output head and affect the stability of the laser. At the same time, the damage caused by such reasons, the long maintenance cycle, and the high repair price tend to result in serious economic losses.

To ensure the long-term stability of the laser, be sure to check and clean the QBH before disassembling and connecting the QBH output.

I. Checking and cleaning tools

1. A microscope with a light source (or a designed jig to clean QBH)

2. Chipless lens tissue

3. Chipless cleaning cotton swab

4. Anhydrous ethanol (anhydrous alcohol, concentration above 99.7%)

II. Operation steps

1. Choose a relatively clean room where there are no dust particles in the air for cleaning.

2. Remove the dust cap and put it upside down on a clean table to prevent dust from entering.

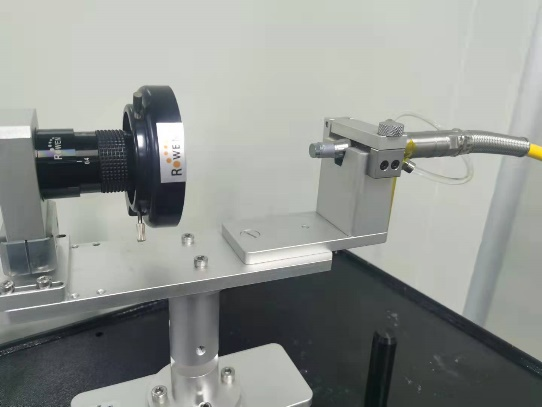

3. Place the QBH output in the microscope holder and fasten it, as shown in Fig. 1-1.

Fig. 1-1

4. If there is no holder for such microscope, it can held in hand for observations as shown in Fig. 1-2.

Fig. 1-2.

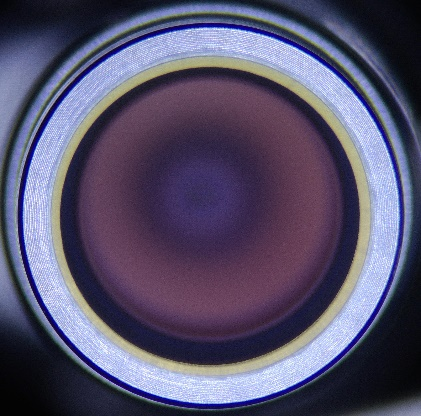

5. Adjust the magnification of the microscope and adjust the brightness of the fill light until a clear, vision-filled outer surface of the QBH output is observed as shown in Fig. 1-3.

Fig. 1-3

6. Carefully observe the outer surface of the QBH output through the microscope. If visible dirt is found, it must be cleaned. If there is visible dirt inside, please contact us. If there is no dust, skip to Step 12.

7. Dip the lens tissue with an appropriate amount of anhydrous ethanol or methanol.

8. Stick to the outer surface with the wet tissue and drag it slowly parallel to the surface until there is no dirt or cleaning reagent left on the surface. Each lens tissue can only be used once.

9. Dip the cleaning cotton swab with an appropriate amount of anhydrous ethanol or methanol.

10. Gently wipe the outer surface in one direction with a cotton swab. Be careful not to scratch the diaphragm. Each cotton swab can only be used once as shown in Fig. 1-4.

Fig. 1-4

11. After wiping, use a microscope to observe the outer surface of the QBH output again to make sure it is clean. If it is clean, repeat Steps 7-10.

12. Immediately install the clean QBH output on the optical components such as the cutting head or welding head to prevent secondary pollution.Remember to keep the QBH output inserted horizontally with the optical components during installation. If not installed, clean and cover the QBH dust cap.