Under the promotion of the national "dual carbon" goals, the development of the new energy vehicle industry has become a key point to solve the shortage of oil resources and reduce air pollution. With the rapid development of the new energy vehicle industry, the continuous improvement of the safety performance of the power batteries, the core component of new energy electric vehicles, is of great significance to electric vehicles.

At present, a large number of laser processing is introduced in the manufacturing process of power batteries. In the process of laser welding, especially high-power laser welding, it is easy to cause spatters and reduce the quality of workpieces. In response to this pain point, Everfoton has developed a new generation of Variable Beam Profile (VBP) Fiber Laser, which can effectively suppress spatter and improve processing efficiency and quality while ensuring high-power and high-speed welding.

Suppression of welding spatters

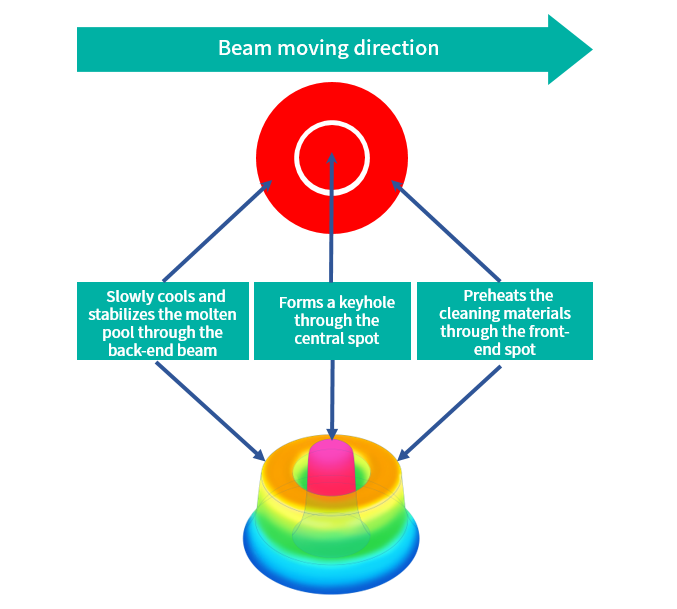

In the welding process, the VBP fiber lasers preheats the cleaning materials through the front-end beam, forms a keyhole through the central spot, and slowly cools and stabilizes the molten pool through the back-end spot, effectively suppressing spatter, reducing the generation of welding pores, and improving the welding quality and yield. It is especially effective in the welding of aluminum and copper materials widely used in the power battery industry.

Principle of suppressing welding spatter by VBP fiber laser

Variable beam design

The self-developed ring fiber can realize different modes such as Gaussian beam, Ring beam, Ring+Gaussian beam, and arbitrary power ratio output of fiber core/outer ring. The waveform parameters of the center beam and the outer ring beam can be edited independently, and the combination of different waveform parameter curves called by the center and the outer ring can be supported. By adjusting the power of the center area and the annular area to change the energy distribution form of the output spot, the spark splash can be effectively reduced. The weld surface is thus more flat and smooth, with deeper and wider penetration.

Multi-stages anti-back reflection protections

The laser is internally designed with multi-stages anti-back reflection protections, and stable energy coupling can realize the processing of various non-ferrous metals (red copper, brass, aluminum, etc.). So it is suitable for various applications of highly reflective materials.

Welding of highly reflective material by VBP fiber laser (left: copper welding, right: aluminum welding)

Welding of dissimilar materials

The excellent beam quality can effectively inhibit the formation of metal compounds during welding and is more suitable for welding dissimilar materials.

Welding of dissimilar materials by VBP fiber laser (aluminum-copper welding)

Variable Beam Profile Fiber Lasers launched by Everfoton can effectively solve the spatter problem in the production process of power batteries and improve the product reliability. The VBP beam-controllable CW Fiber Laser can also realize output of special fibers of various specifications including 14/100μm, 50/150μm, and 100/600μm, with a total output power of up to 12kW, which can better meet the needs of different applications for ring beam mode distribution.

In the future, Everfoton will continue to optimize and upgrade, focus on integrated innovation, break through key core technologies, provide high-quality and efficient solutions for the manufacturing of new energy power batteries, help the safe and efficient production of the new energy vehicle industry, and contribute to the breakthrough of core technologies and industrial upgrading of the industry.