Everfoton achieves vertical integration in the industry chain of fiber laser

Everfoton Technologies Corporation Limited (Everfoton), a subsidiary of Yangtze Optical Fiber and Cable Joint Stock Limited Company (YOFC) (stock ticker symbol: 601869.SH, 06869.HK), is the only entity that engages in fiber laser business on behalf of YOFC. Everfoton vertically integrates the fiber laser industry chain. In December 2021, YOFC injected all fiber laser-related businesses of materials, specialty fibers and components into Everfoton. In April 2022, Nanjing fiberfoton Technologies Corporation Limited (Fiberfoton) was acquired by Everfoton as its wholly owned subsidiary. Fiberfoton has been working in the field of fiber laser for many years, and has many top talents and key technologies in the fields of chip, pump and fiber laser. With benefits brought by vertical integration throughout the whole industry chain, Everfoton is able to provide global users with high-quality and differentiated fiber laser application solutions.

Technological advantages throughout the whole industry chain

Everfoton has an advanced R&D and manufacturing platform and many key technologies for the whole industry chain of fiber lasers.

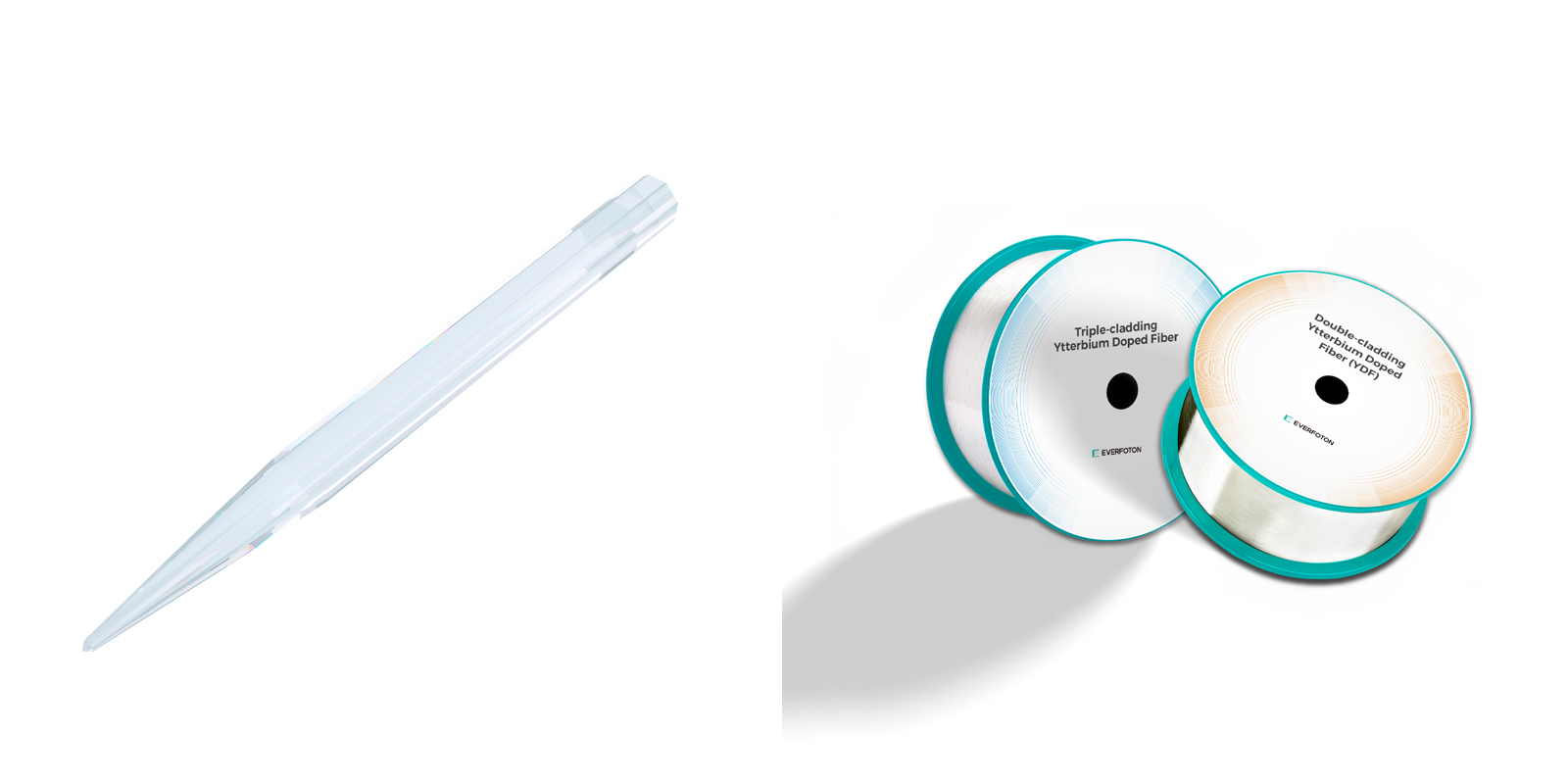

Key technology: high-power active fibers

After more than a decade of technological development accumulation, Everfoton's rare-earth doped technique can be on a par with the international leading level. In 2018, it took the lead in developing triple-cladding active fiber in China, and has a sizable production capacity of double-cladding and triple-cladding active fiber. The output power of active fiber continues to improve, and at present, the single fiber stable output power of ytterbium doped fiber is up to 6kW, leading the industry’s technological development.

Preform and fiber

Key technology: broad portfolio of passive fibers

With over 30-years track record of PCVD technology and the plantform, Everfoton has built a domestically largest platform of passive fibers for lasers which offers a broad portfolio of technologies and products, able to produce passive fibers for lasers in large scale . Over recent years, Everfoton rapidly rolled out new products like ring fibers, homogenized fibers, large core fibers and polarization maintaining passive double-cladding fibers to facilitate applications of fiber lasers in fields like new energy battery welding, precision cutting, laser cladding and other segments. It fully demonstrates the proven technological strengths of Everfoton’s PCVD platform and its ability to be responsive and offer customized solutions for industrial applications.

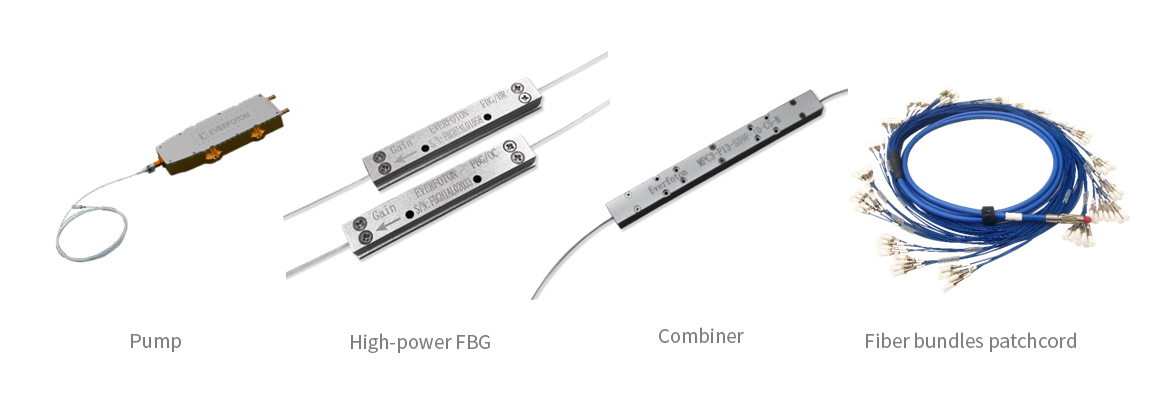

Key technology: pumps, high-power FBG and other key assemblies and components

Everfoton has mastered the key technologies of pump package, FBG, combiner, QBH and other laser key assemblies and components, underpinning superior quality and high performance fiber lasers.

The pumps is well-designed and features light weight, small size and high output power, and automatic manufacturing platforms have also been built.

Automatic UV FBG writing and ultrafast femtosecond FBG writing platforms have been developed. The single-cavity high-power (up to 5kW) FBG, high-power femtosecond FBG, Raman suppression FBG and many other highly reliable FBG have been rolled out. Everfoton is able to develop customized FBG of various types.

Vertical integration enables high-quality and differentiated fiber laser solutions

Vertical integration throughout the whole industry chain and leading technologies put Everfoton in a good position provide intelligent, high quality and differentiated fiber laser solutions, including multiple customizable wavelengths, different beam modes, quasi-continuous wave, narrow linewidth and ultrashort pulse.

Everfoton, a leader in small-size, lightweight and portable lasers, has developed 10kg 500W portable air-cooled high-brightness lasers, knapsack-type air-cooled kilowatt-class handheld laser welding machines, and other lightweight and portable products.

At present, Everfoton has developed into a series of fiber laser solutions, with power ranging from hundred watts to million watts level, covering sheet metal cutting, new energy battery welding, metal 3D printing, laser melting, laser cleaning and many other niche fields.

In the future, Everfoton will exploit the benefits created by vertical integration throughout the whole industry chain, provide high-quality, differentiated and intelligent laser application solutions with ingenuity and craftsmanship and devote itself to enabling a better life with leading light technology.